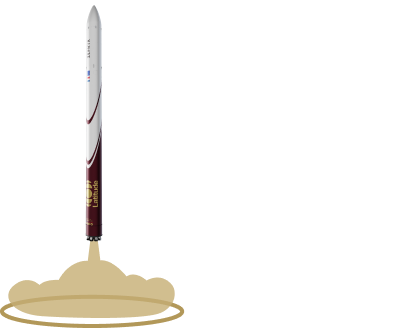

Proven Performance, Trusted Technology

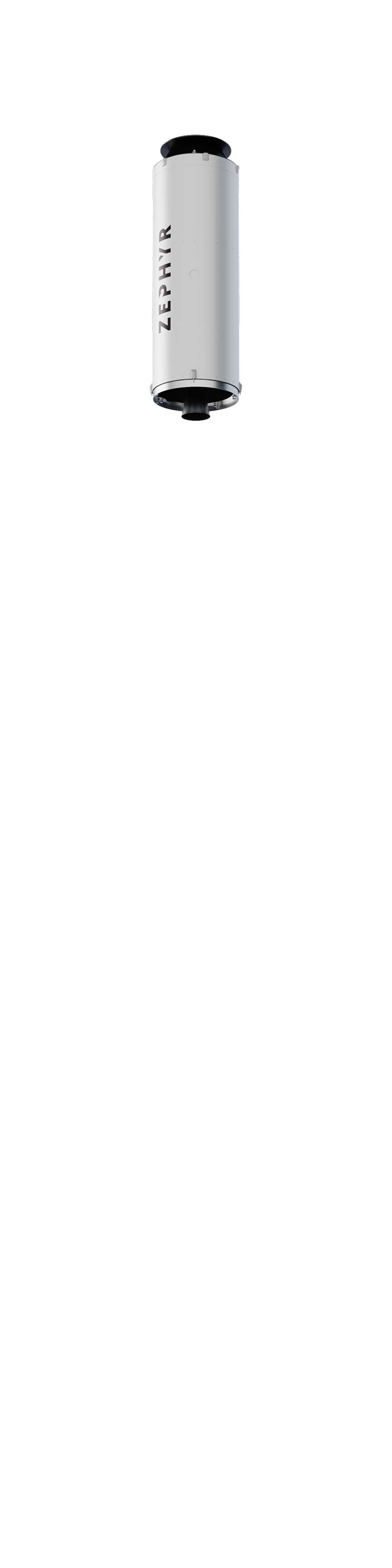

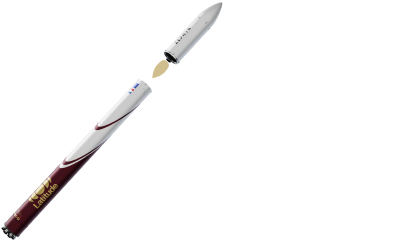

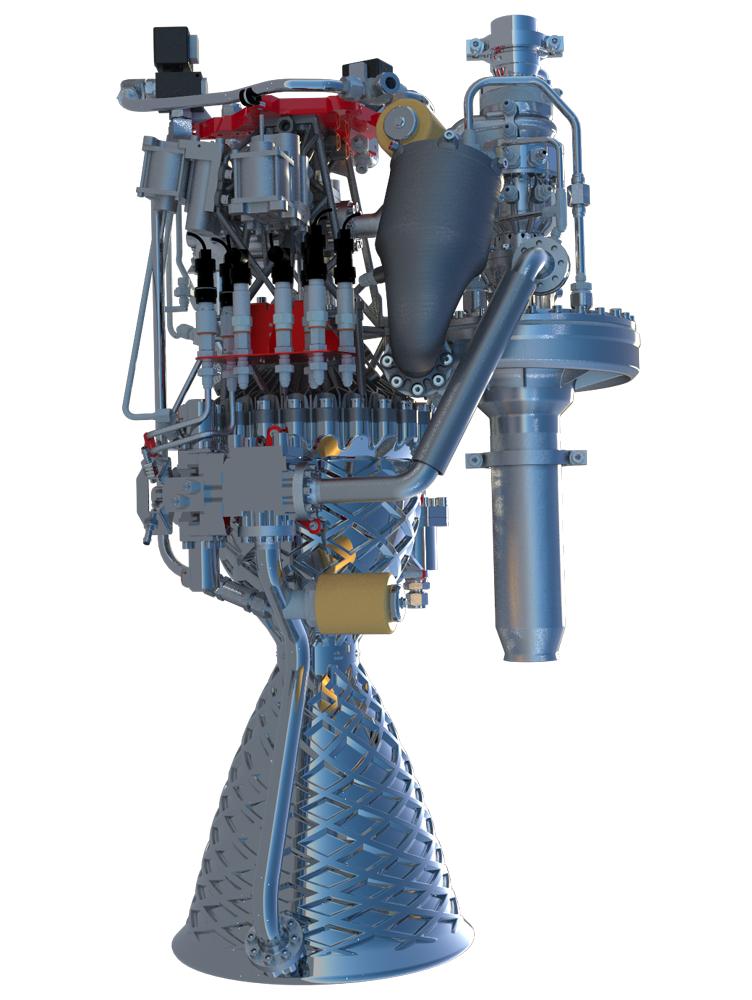

The Navier engines, fully designed in-house and 3D-printed, drive both stages of the rocket, delivering high performance.

They operate on the LOx-RP1 propellant combination, a proven and reliable choice that has powered countless space missions, ensuring efficiency, stability, and trust in every launch.

;)

;)

;)

;)

;)

;)